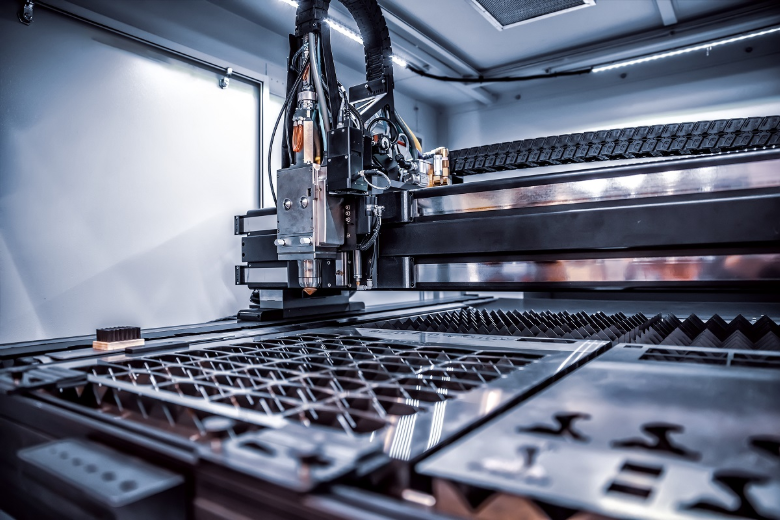

Laser cutting is an advanced technology used to cut, carve, or engrave materials with great precision. This technique uses a focused laser beam to melt, burn, or vaporize the material in the desired shape.

Laser cutting is widely used in industries like manufacturing, automotive, and even art. In this post, we will explore five major benefits of laser cutting and how it makes the process more efficient and accurate.

1. Precision and Accuracy

One of the biggest benefits of laser cutting is its extreme precision. A laser cutter can create shapes and designs with incredible detail. The laser beam is very narrow, which means it can make cuts with very fine tolerances.

This accuracy is especially important in industries like aerospace and electronics, where even the smallest mistake can lead to problems. Laser cutting helps reduce errors and ensures high-quality results every time.

2. Speed and Efficiency

Laser cutting is faster than traditional cutting methods. The laser can cut through materials at a rapid speed, making the whole process more efficient. Because of its speed, laser cutting is perfect for mass production or situations where time is limited.

Since the machine is controlled by a computer, there is also less need for manual adjustments. This leads to fewer delays and faster turnaround times.

3. Versatility with Materials

Laser cutting is incredibly versatile when it comes to the types of materials it can work with. It can cut through a variety of materials such as metals, wood, plastic, and even fabrics. This flexibility makes it a great tool for many different industries.

Whether you’re working on a simple wood project or a complex metal design, laser cutting can handle a wide range of materials with ease. Additionally, it can be used for both thick and thin materials, making it adaptable to various needs.

4. Clean and Smooth Edges

Laser cutting produces clean and smooth edges on materials. This is a big advantage over other cutting methods, which can sometimes leave rough edges that need to be smoothed out later. Since the laser beam melts the material as it cuts, the edges are smooth and do not require extra finishing. This not only saves time but also improves the overall quality of the final product.

5. Reduced Waste

Laser cutting helps reduce waste. Since the laser beam is so precise, it can make cuts with very little material left over. This is especially beneficial when working with expensive materials, as it helps to use every bit efficiently.

Additionally, the technology allows for optimized designs that make the most of the material, reducing the amount of waste generated in the production process.

Conclusion

In conclusion, laser cutting offers a variety of benefits that make it a preferred choice in many industries. From its high precision and speed to the ability to work with different materials, this technology has proven to be both efficient and cost-effective.

With the added advantage of clean edges and reduced waste, laser cutting is revolutionizing how we create and manufacture products. If you’re looking for a cutting method that combines accuracy, efficiency, and versatility, laser cutting is definitely the way to go!